First Time Yield, the most common way to calculate process yield, is the probability of a defect-free output from a process. This metric considers only the criteria at the end of the process. FTY is unit sensitive, meaning it does not take into account whether the output unit is defective, and is calculated by dividing the number of units produced from a process by its inputs. It does not capture how many defects were found and corrected within a single unit.

The FTY will not detect the effect of hidden factories. Consequently, it will typically indicate that a process is performing better than it really is. Even so, it is a frequently used metric in businesses because, in part, of the way, some companies report their performance to financial analysts.

First Time Yield Calculation

The results of calculating yield the traditional way are misleading because they don’t account for the intricacies of the process. The calculation known as first-time yield (FTY) is often much different than traditional yield. That’s because, unlike traditional yield, it captures the harsh reality of the effectiveness of the process.

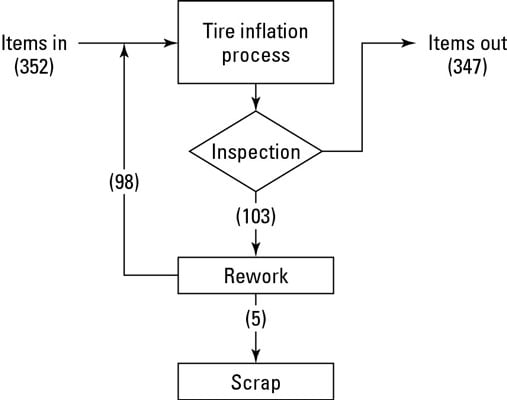

After inflation, the tire is immediately inspected to make sure it meets the required pressure specification limits. In the example, 103 tires are detected that don’t comply with the pressure specification.

Of course, the operators of the process reviewed each of these 103 and corrected (or reworked) 98 of them, leaving only five that they couldn’t bring back within the correct pressure range and had to scrap. With this detailed information, you now know that the proportion of tires going through the inflation process correctly the first time is

![]()

or 70.7 per cent

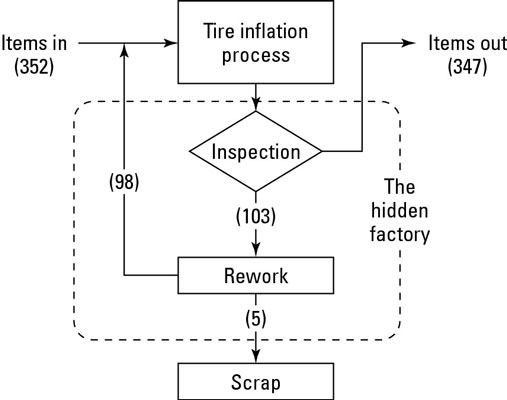

How to uncover the hidden factory

The hidden factory is a natural outgrowth of a system’s inability to correctly comply with required specifications the first time through the process. Here and there throughout organisations, rework and fix practices arise and become engrained as “that’s just the way we do it” parts of the standard practices. But if you measure yield by using the first-time yield method you naturally objectively review and acknowledge process effectiveness.

In the case of the example tire-inflation process, the hidden factory of in-process inspection and rework accounts for 0.986 – 0.707 = 0.279 or 27.9 percent of production. All together, value-sapping hidden factories within organisations combine to consume valuable resources and time.

Source: Craig Gygi

Course Overview

Our Lean Six Sigma courses provide in-depth training on FTY calculations and its importance in production processes, measuring the quality and efficiency of a process by evaluating the proportion of defect-free units produced. Our Lean Six Sigma courses equip professionals with the knowledge and tools needed to master FTY and drive continuous improvement in their organisations. Join us to learn from industry experts and take your career to the next level.

Benefits of Understanding FTY

-

Enhanced Quality Control: By focusing on FTY, organisations can significantly reduce defects and improve product quality.

-

Increased Efficiency: Higher FTY rates indicate a more efficient process, leading to reduced waste and cost savings.

-

Data-Driven Improvements: Using FTY metrics enables targeted improvements based on precise data analysis.

- Customer Satisfaction: Producing defect-free products the first time ensures higher customer satisfaction and loyaly

Lean Six Sigma | Measure: Rolled Throughput Yield (RTY)

Lean • Lean Six Sigma • Lean Six Sigma Training

Lean Six Sigma | Measure: Rolled Throughput Yield (RTY)

Lean • Lean Six Sigma • Lean Six Sigma Training

Lean Six Sigma | Measure: Defects per Million Opportunities (DPMO)

Lean • Lean Six Sigma • Lean Six Sigma Training

Lean Six Sigma | Measure: Defects per Million Opportunities (DPMO)

Lean • Lean Six Sigma • Lean Six Sigma Training